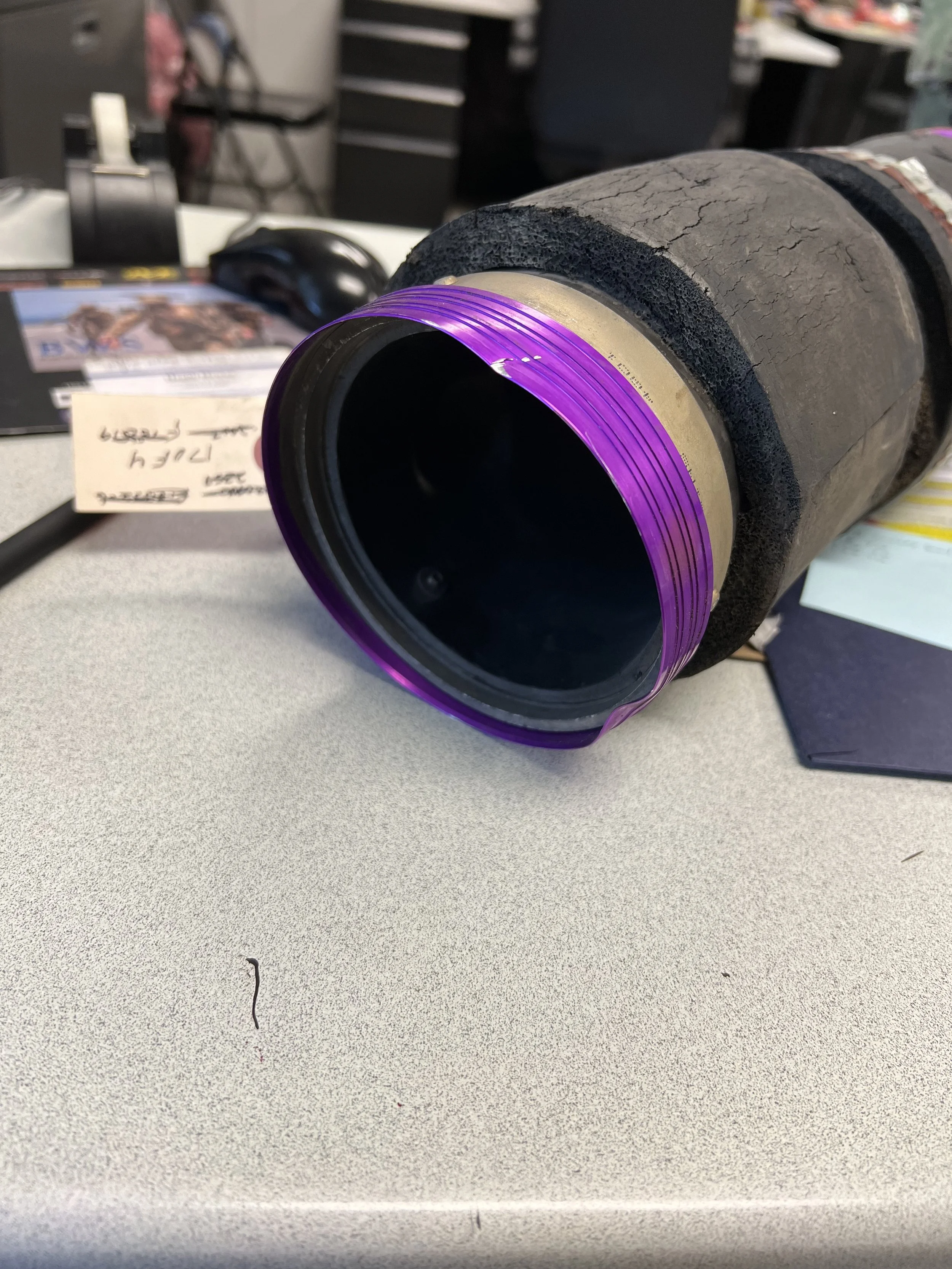

As you can see, there are tool marks in the sleeve. This is from a technician using a flat head or pryer to get the sleeve into place. This is dangerous since the nick in the sleeve can actually roll over the o-ring and cut it. This will lead to a leak in the system!! With GlideGuide, this CANNOT happen as there are no sharp marks or edges and it applied even pressure on installation!

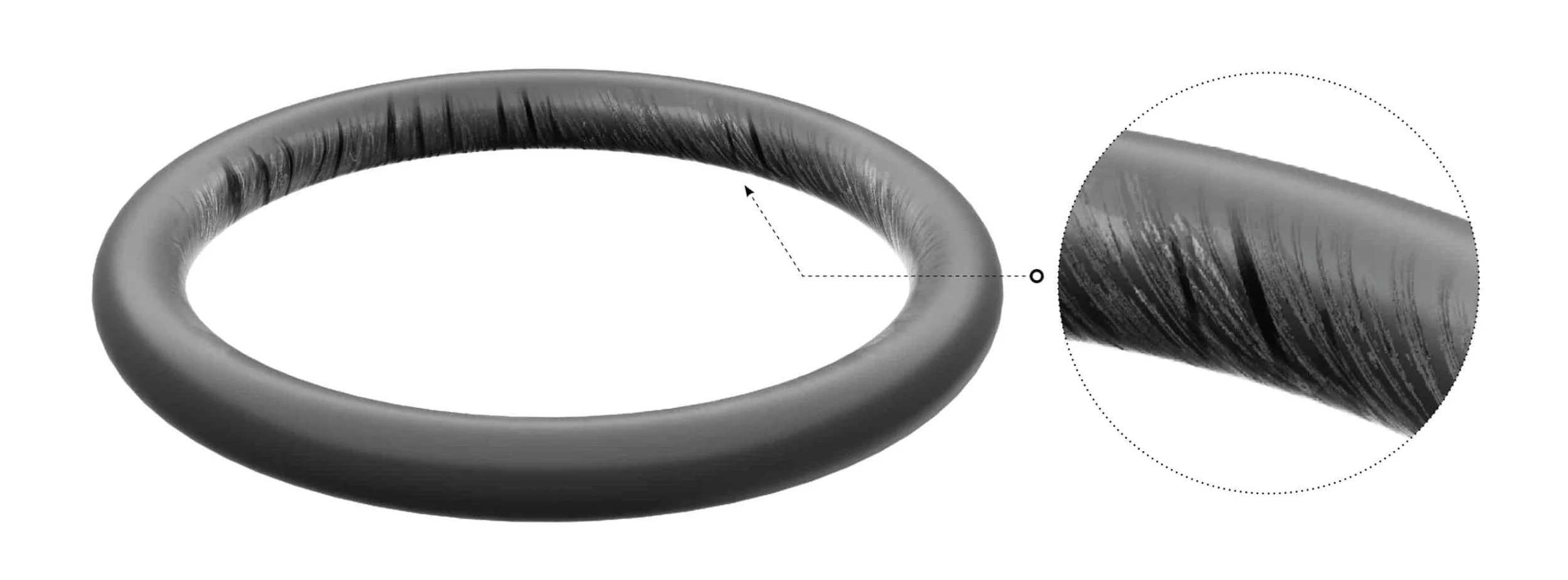

This is an example of a rolled O-Ring. This will happen if the O-ring isn’t lubricated prior to installation, OR if the technician “walks” the sleeve onto the end ferruls causing the o-ring to “candy-cane” or twist in its groove. This is worse case scenario due to the fact that the system will hold pressure at first!! BUT repeated use will cause the o ring to deteriorate and leak causing the aircraft to be down and needing repairs. Using GlideGuide to apply even pressure on the sleeve during installation will save tens of thousands of dollars in repair cost and aircraft down time.

The image below is the ECS system of a new Boeing 787 Dreamliner aircraft. All the purple fittings between the lines are slit-fit style fittings. There are a total of 11 fittings just in this picture alone. Now imagine the rest of the aircraft. These fittings are in the wings for fuel, and in the fuselage for the environmental control system. Hundreds are these are used on this aircraft alone, and anyone of those could have been installed incorrectly, have a nick in the sleeve, or a rolled o-ring. GlideGuide will save TIME & MONEY & MAN HOURS when it comes to fuel, pneumatic, ECS, or lavatory maintenance on your aircraft.

Inside of fuel tanks is where GlideGuide is really going to be useful. Fuel tank maintenance is an absolute pain to do, you have to crawl around in tight spaces and sometimes the job you’re performing isn’t right in front of you, sometimes you can only use one hand. With GlideGuide, the sleeve can be set WITH ONE HAND!! techs will not have to use damaging flatheads, prybars, or pliers anymore!